What if I told you waste is not a problem, but a decision?

When we think of large infrastructure projects like bridges, rail networks, and airports, most people picture the scale, the engineering marvels, and the deadlines.

But when you tuck away behind all that progress, you will find a silent burden of not reducing construction waste.

And not understanding how to reduce construction waste is not just a nuisance. It’s a major cost driver, a safety concern, and a red flag for sustainability.

In countries where infrastructure is booming, the numbers are staggering. As construction and demolition waste already forms a significant portion of urban waste, some estimates peg it at more than one-third of the total volume of all waste generated.

And when the dust settles on a project, the debris left behind tells a story of missed planning and preventable loss.

Among all of these, the real question is how we can shift that narrative? How can we do away with the junk generated by construction projects, and build smarter buildings with less waste and more purpose?

First, let’s begin by understanding

What is Construction Waste in Infrastructure Projects?

It’s easy to underestimate just how much material gets wasted on a site. We’re not just talking about leftover bricks or the odd steel rod.

The list of construction costs is long, as it includes

- Broken tiles, damaged cement bags, and extra concrete

- Packaging waste from machinery or material transport

- Debris from site clearance or redesigns

- Bits and pieces that never made it into the structure

Moreover, when these projects are large-scale, the scale multiplies quickly. All it takes is one design change or a material delay, and the chain reaction begins with discarded materials, rework, and inefficiencies.

And what causes all this? Most of the time, it’s not negligence. It’s the system. For instance,

- Designs that don’t factor in material usage properly

- Estimates that err on the side of excess

- On-ground handling that damages more than it builds

- Evolving project demands that undo earlier work

That’s why reducing construction waste isn’t just a site-level issue, it’s something that needs to be tackled from day one.

How to Reduce Construction Waste? Proven Strategies for Large Infrastructure Projects

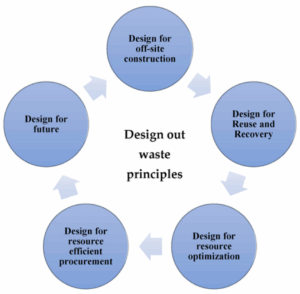

Image source: https://www.mdpi.com/2071-1050/14/6/3410

Well, when it comes to reducing construction waste, there’s no one single hack. But there is a way forward, and it starts with intention.

If you’re asking how to reduce construction waste on massive sites, here’s what actually works:

Start planning before laying the first brick.

- Get your quantity estimates as tight as possible. Overordering is one of the biggest culprits.

- Go for modular designs and prefab components wherever feasible. They’re cleaner, faster, and leave less behind.

When you source, think smarter.

- Adopt a just-in-time delivery model. No point hoarding materials that might get spoiled before use.

- Choose suppliers who offer reusable or recyclable materials like steel with high scrap value, reusable formwork, or recycled aggregates.

Handle on-site tasks with care.

- Set up proper zones for material storage. A little shelter goes a long way in avoiding damage from rain or mishandling.

- Make waste segregation a norm, not an afterthought.

Use tech to make a difference.

- Tools like BIM (Building Information Modelling) allow for clash detection and more accurate planning.

- AI tools can predict waste-prone stages based on past project data.

Train your people.

- A well-trained workforce knows how to avoid rework. They get things right the first time.

- Additionally, encourage on-site awareness of sustainability practices. Today, it’s not just a corporate value, it’s a daily discipline.

MMCPL’s Waste-Reduction Approach in Action for Infrastructure Projects

At MMCPL, reducing construction waste is not just in books. Our team regularly brainstorms on how to reduce construction waste across every site that we work on. It’s baked into how we approach engineering—from building bridges to urban planning.

From day one, our designs are checked not just for technical strength but also for material efficiency.

For example:

In recent infrastructure builds, we’ve used prefabricated structures that cut down raw material use and site debris significantly.

- By investing time in design precision, we’ve reduced the need for on-site corrections, and with that, the amount of waste generated.

- On one of our industrial park projects, leftover material was systematically repurposed for future internal use, so nothing went to landfill.

What helps is our clear focus on process and alignment. Everyone from our engineers, project managers, and on-site crew to even vendors, are on the same page when it comes to reducing construction waste and improving sustainability.

Potential Challenges in Reducing Construction Waste

As much as we’d like to believe construction waste reduction is simple, the reality is layered because,

There are industry-level barriers such as

- It’s not always easy to find reliable vendors for recycled materials.

- Traditional contractors might resist change, especially when short-term convenience is involved.

- Even now, some projects are slow to adopt technology, which could have prevented the waste in the first place.

Frequently, site-level issues prop up, including

- Teams are just not aware of the impact their choices have.

- Projects become too complex as multiple players get involved, and then coordination becomes a problem.

- Tight timelines and cut corners lead to waste in multiple areas.

At MMCPL, we don’t pretend these challenges don’t exist. And to overcome them, we face them head-on with better systems, clear communication, and a strong commitment to reducing construction waste.

Whether it’s tech adoption, vendor coordination, or team awareness, we treat it all as part of the engineering journey.

What’s next? The future of waste reduction in construction

When it comes to reducing construction waste, things are changing, and they are changing fast. Such as:

- Circular construction: Projects are being designed with end-of-life reuse in mind.

- Carbon credits may soon be linked to how much waste you cut, not just how green your materials are.

- Certifications like IGBC and GRIHA are no longer “nice to have.” They’re becoming the new benchmark.

At MMCPL, we’re ready for this shift. We’re investing in tools, people, and partnerships that help us lead, not follow, in sustainable infrastructure delivery.

Work With MMCPL to Reduce Construction Waste in Large Infrastructure Projects

At the end of the day, reducing construction waste is not just a sustainability checkbox. It’s a reflection of how thoughtful your planning is, how aligned your teams are, and how committed you are to long-term value.

For us at MMCPL, it’s simply how we work.

Whether you’re a builder, engineer, or decision-maker, NOW is the time to rethink how your next project treats its waste. Let’s build with purpose. Let’s build responsibly.

Talk to MMCPL to explore how we can help reduce construction waste without compromising scale, speed, or quality.